| Topic: New car engine is world changing | |

|---|---|

|

Edited by

wux

on

Sat 05/19/12 06:48 PM

|

|

|

Because... the explosion in the chamber does not move anything against anything else. It is in an enclosed space, which can't expand; there is no way the explosion is contributing with any sort of force or work to any motion. When I first looked at the diagram, the same question went through my mind. I think the answer lies in the spiral curvature of the fans. Consider this guy:

If you took this vent and sealed off the inside, then placed a series of firecrackers inside the vent flaps, and ignited them sequentially, it would be a vaguely similar situation. At first it might seem that the fire crackers exert force on both sides equally - which is probably true in the first instant of explosion. But as the expanding gas tries to escape that region, the curvature of the blades forces the air to leave in one direction, causing the vent to turn just as if air was being forced through it. I think the same principle applies to this engine. The rotation is due to the fact that the expanding gas is forced to escape with a biased direction, due to the curvature of the blades. Mind you, I'm not claiming to know that this is true in this situation. I haven't really looked at it, so I don't really understand it. Its just a theory that makes sense to me. This might be true if the chambers were open. But the chambers do not open before, during, and after the explosion in the "engine". If what you describe just here above is what happened, then it would be a jet-engine... or rather, not jet, but a rocket engine. The escaping gas would propel the engine housing in the opposite direction of its escape. I referred to this in my post, but I called it "jet" action, whereas I ought to have said "rocket" propelling action. And it would be silly to create a roating base for a rocket engine... unless it's good for the regulating of its firing off, which I won't deny is good as per the given design. Maybe the real design is a rocket engine, and this is a way of controlling the amount of acceleration to the rocket (car) to keep it variable and controllable due to driving conditions, obstacles, and traffic rules. If this is the case, then this is not an engine, and the efficiency math does not work out at all. In any case, this design would not turn the engine shaft; it would need external force for it to turn and to keep turning. |

|

|

|

|

|

Edited by

massagetrade

on

Sat 05/19/12 07:20 PM

|

|

|

Because... the explosion in the chamber does not move anything against anything else. It is in an enclosed space, which can't expand; there is no way the explosion is contributing with any sort of force or work to any motion. When I first looked at the diagram, the same question went through my mind. I think the answer lies in the spiral curvature of the fans. Consider this guy:

If you took this vent and sealed off the inside, then placed a series of firecrackers inside the vent flaps, and ignited them sequentially, it would be a vaguely similar situation. At first it might seem that the fire crackers exert force on both sides equally - which is probably true in the first instant of explosion. But as the expanding gas tries to escape that region, the curvature of the blades forces the air to leave in one direction, causing the vent to turn just as if air was being forced through it. I think the same principle applies to this engine. The rotation is due to the fact that the expanding gas is forced to escape with a biased direction, due to the curvature of the blades. Mind you, I'm not claiming to know that this is true in this situation. I haven't really looked at it, so I don't really understand it. Its just a theory that makes sense to me. This might be true if the chambers were open. But the chambers do not open before, during, and after the explosion in the "engine". This may be true, but I'm not convinced that this is true. We need to look at the angular velocity and the angle between the moment of explosion and the moment of venting. It seems to me that the chambers might very well vent very shortly after the detonation. Edit: 'very shortly' being an understatement. I mean to say: so soon afterwards, that as far as the escaping gas is concerned, it might as well be the same instant. rocket engine, and this is a way of controlling the amount of acceleration to the rocket (car) to keep it variable and controllable due to driving conditions, obstacles, and traffic rules.

I could be wrong, but I've been assuming its intended to be placed in a serial hybrid, so that the the activity of the engine can be tuned solely for generating electricity, completely ignoring variable demands created by variable driving conditions. (The electrical propulsion system would need to respond to those demands.) |

|

|

|

|

|

Edited by

metalwing

on

Sun 05/20/12 06:11 AM

|

|

|

Massage is correct. The engine is tuned to run at basically one rpm, which is the rpm for maximum efficiency. And the curved shape has everything to do with it. All the accelerated gas is deflected in the pressure wave leaving a F=Ma sweet spot. Bristance plays a large role.

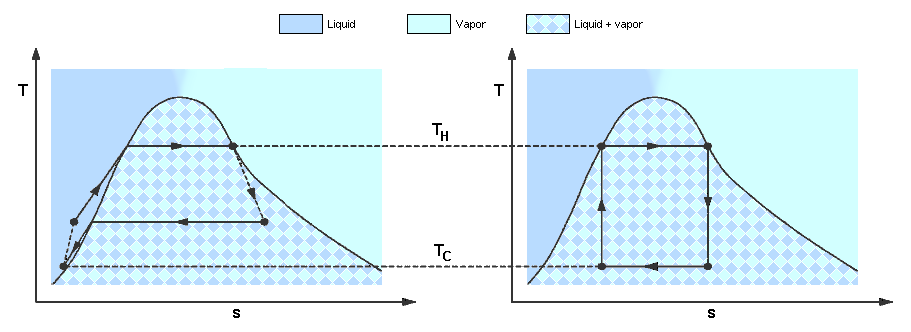

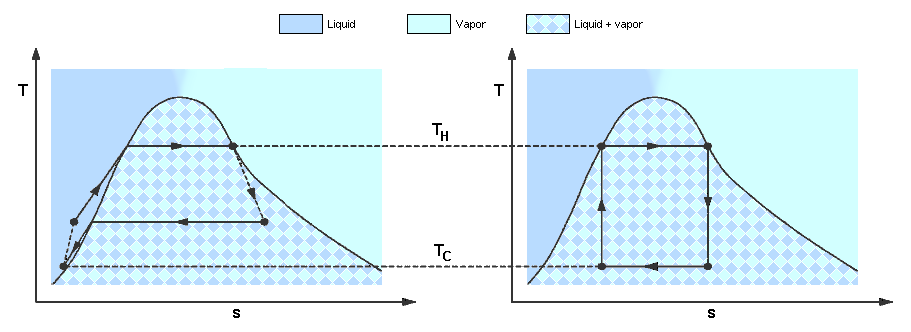

And Wux 45% may be the maximum theoretical efficiency for a Carnot cycle (for example), but that fact doesn't apply here and does not enter into the efficiency calculations. In the real world engine manufacturers struggle to get about 30% efficiency MAXIMUM out of their engines and that is at a certain rpm also ... usually near the point where the torque curve crosses the horsepower curve. In the real world car engines run at many different rpms and average something closer to 15% efficiency. Three and a half times that still leaves heat going out the tailpipe.

|

|

|

|

|

|

Massage is correct. The engine is tuned to run at basically one rpm, which is the rpm for maximum efficiency. And the curved shape has everything to do with it. All the accelerated gas is deflected in the pressure wave leaving a F=Ma sweet spot. Bristance plays a large role. And Wux 45% may be the maximum theoretical efficiency for a Carnot cycle (for example), but that fact doesn't apply here and does not enter into the efficiency calculations. In the real world engine manufacturers struggle to get about 30% efficiency MAXIMUM out of their engines and that is at a certain rpm also ... usually near the point where the torque curve crosses the horsepower curve. In the real world car engines run at many different rpms and average something closer to 15% efficiency. Three and a half times that still leaves heat going out the tailpipe.  Really 1 rpm? With 15 chambers, and 2 combustion locations, thats (1 rotation / minute) (1 minute / 60 seconds) (30 detonations / rotation) = 1 detonation every 2 seconds. That seems way too slow. http://en.wikipedia.org/wiki/Brisance |

|

|

|

|

|

Edited by

wux

on

Sun 05/20/12 08:50 AM

|

|

|

Okay. I suggest you do this experiment:

You take a bullet, take out the shot, and leave the gunpowder in the shell. Take a can of Beans, cut out both end pieces, and empty the can. Then put the can between two very parallel plates, and put the can in between, put the gunpoweder in the can, and press down lightly on the top plate, to make the air escape routes impossible, but not press so hard that the can can't move. Now ignite the gunpowder. (Heat the bottom plate with lighter under the area where the gun powder is.) Don't put so much gunpoweder that it will throw the contraption into pieces, only enough to make a smallish explosion that is not dangerous. Then report if the can moves in any direction as an effect of the explosion. Report also if you can, how much moving energy is generated. After this, if the can moves much less in your estimation than what the energy that's been stored in the gunpoweder, then keep re-shaping the can, in any and every way you can, to excite it to move at the time of the ensuing explosions, provided that you keep the two openings flat, and fitting to the parallel plates on their sides. I am trying to say that in an enclosed space, if there is a freely moving thing, and inside of it an explosion happens that does not move two or more parts of this thing relative to each other, then there is no other movement the explosion will generate. If the movement is starting at the time when there is an opening in the system to the outside world, then there is rocket-propulsion action. The engine of the diagram as it is drawn does not create movement at all, I still hold to this claim. 00000000000000000 Regarding the calculations: I did take into effect the unmentioned variables, and I did redifine the original setup, which did not define its own measurements, vis-a-vis its own conditions. In real effect, the efficiency of a car, or its engine, when it is used to transport a person, is defined the energy it takes to transport the person, over the energy it takes to operate the engine. Once you get away from electric bikes, or Harvey Davidsons, and get into cars, this ratio is less than one percent for sure. So... you are right in your calculations... what I object to is that your calculations and mine are conjectures, inasmuch as both yours and mine want to second-guess the original article's meaning, because the original article said nothing about how they calculated the claimed factor of improvement in efficiency. In other words, you have the right to reject my calculations, and I have the right to reject yours, because although we both are correct in our physics and in our math, neither of us has any clue how the article's claim of improvement factor was calculated. |

|

|

|

|

|

Okay. I suggest you do this experiment: ... Then report if the can moves in any direction as an effect of the explosion. I with you there, Wux. I'm assuming others are. There is no net movement without a net force. I'm still not clear on the delay between detonation and 'rotation to the point where one side is open' - if its fast enough, it might be misleading to think in terms of whether the chamber is open at the 'instant' of detonation. It's true that there is a single instant at which the detonation starts, but the detonation process, the expanding gas process, spans a (admittedly short) period of time. If the movement is starting at the time when there is an opening in the system to the outside world, then there is rocket-propulsion action.

Yes - while I don't pretend to understand this engine (yet), just from looking at the picture I think that the force of the escaping, expanding gas is key to making this work - and that it is akin to the rotating vent shown in the photo I posted. I see why you would call this "rocket propulsion action", but I'm not sure if you are also implying that this invalidates the idea of evaluating this as a variation of a heat engine. The engine of the diagram as it is drawn does not create movement at all, I still hold to this claim.

So you are saying that, as diagrammed, that it is impossible for escaping gas to cause rotation? |

|

|

|

|

|

Edited by

metalwing

on

Sun 05/20/12 12:13 PM

|

|

|

Okay. I suggest you do this experiment: ... Then report if the can moves in any direction as an effect of the explosion. I with you there, Wux. I'm assuming others are. There is no net movement without a net force. I'm still not clear on the delay between detonation and 'rotation to the point where one side is open' - if its fast enough, it might be misleading to think in terms of whether the chamber is open at the 'instant' of detonation. It's true that there is a single instant at which the detonation starts, but the detonation process, the expanding gas process, spans a (admittedly short) period of time. If the movement is starting at the time when there is an opening in the system to the outside world, then there is rocket-propulsion action.

Yes - while I don't pretend to understand this engine (yet), just from looking at the picture I think that the force of the escaping, expanding gas is key to making this work - and that it is akin to the rotating vent shown in the photo I posted. I see why you would call this "rocket propulsion action", but I'm not sure if you are also implying that this invalidates the idea of evaluating this as a variation of a heat engine. The engine of the diagram as it is drawn does not create movement at all, I still hold to this claim.

So you are saying that, as diagrammed, that it is impossible for escaping gas to cause rotation? Well, let me explain the cycle a little differently. Carnot, Otto, Sterling, turbine, and rocket Cycles, and similar, are heat engines. A fuel burns causing gas to expand. The pressure of the gas expanding pushes a piston or blows on a turbine blade to create work. A rocket does basically the same thing but simply uses the F=ma of Newton's reaction law to push in one direction. The Laws of Thermodynamics dictate that the work done is a function of the difference between the temperatures and pressures between intake and exhaust. So, with the limits of the materials generally used, the efficiency of a piston engine is limited to around 30%. If the engine start to "Knock" i.e., detonate, the temperatures and pressures will skyrocket melting the pistons and blowing the engine apart. The new engine uses the BRISTANCE of detonating gasoline to create a shock wave the same way as IEDs are used in Iraq to send metal fragments into vehicles to destroy them. The energy is almost instantaneously transformed into a high pressure shock wave. The shock wave impacts a curved turbine-like blade to accelerate the shockwave gas into a different direction. If the curved blade curved 90 degrees of rotation redirecting the high speed expanding gas at right angles to the blade, Newton's law of reaction would "push" on the blade in the opposite direction of the exiting gas with the pressure of the shock wave. This pressure wave is a MUCH higher transmission of power than a piston in a cylinder because most of heat energy leaves the cylinder without doing any work. The blades are not curved a full 90 degrees for a variety of reasons. In the detonation cycle, the shock wave collapses quickly after acting on the rotor blade and it's work is done. The temperature is far cooler than the exhaust of a piston engine due to most of the energy going to bristance, not simple pressure caused by heat expansion of gas. I would guess that the engine runs between 10 and 20,000 rpm but it could be higher. |

|

|

|

|

|

I would guess that the engine runs between 10 and 20,000 rpm but it could be higher. Yes, that would make sense to me. At that speed, it would be misleading to think of the detonation-process occurring fully within the 'instant' that the blades are in the detonation position shown in the diagram. |

|

|

|

|

|

Massage is correct. The engine is tuned to run at basically one rpm, which is the rpm for maximum efficiency. And the curved shape has everything to do with it. All the accelerated gas is deflected in the pressure wave leaving a F=Ma sweet spot. Bristance plays a large role. And Wux 45% may be the maximum theoretical efficiency for a Carnot cycle (for example), but that fact doesn't apply here and does not enter into the efficiency calculations. In the real world engine manufacturers struggle to get about 30% efficiency MAXIMUM out of their engines and that is at a certain rpm also ... usually near the point where the torque curve crosses the horsepower curve. In the real world car engines run at many different rpms and average something closer to 15% efficiency. Three and a half times that still leaves heat going out the tailpipe.  Really 1 rpm? With 15 chambers, and 2 combustion locations, thats (1 rotation / minute) (1 minute / 60 seconds) (30 detonations / rotation) = 1 detonation every 2 seconds. That seems way too slow. http://en.wikipedia.org/wiki/Brisance I just reread this post and burst out laughing. I was wondering where the concept of running the engine at only 1 rpm came from till I saw what I had written.

The engine is based on capturing the energy of the pressure wave of detonation. The pressure wave is very fast and very intense near the origination. The idea is for the wave to impact the impeller blade and impart as much of the wave energy into the blade as possible by forcing the wave to change direction. The reaction turns the blade. LOL I stated that the engine would work best at "one rpm" meaning that there would be a specific rpm (like the old two stroke engines) where the engine would be efficient but not efficient at higher or lower rpms. I suspect that one rpm would be around 20,000 or more to keep the engine able to produce smooth horsepower with a small foot print. |

|

|

|

|

|

A very important point about this engine is that it is not a theory. The engine has been developed and sized such that the working model is appropriate for use in hybrid cars. No scaling is necessary but may apply to future engines.

The number of parts is low and the cost of the engine will be reasonable. They are looking to go into production soon and, if so, will change the landscape of how cars work, how much the fuel contributes to the overall cost to run a car, the life expectancy of current oil reserves, yada yada yada. |

|

|

|

|

|

Edited by

wux

on

Mon 05/21/12 01:39 PM

|

|

|

The diagram does not reflect any of what you said in the last few posts. I go by what I see. Also, there is another iffy thing. You say the temperature will be much lower. How can that be? Burning gasoline burns at a certain temperature. It can't burn at a lower temperature. The ambient pressure affects the temperature, sure, but it does not affect the heat amount or temperature of what a certain carbohydrate molecule produces when it combines with oxygen. The deeper we go into this, the more ill-described it sounds. I don't doubt that the engine may be in the prototype stage. It would be easy to research that, and I don't do research. All I am saying is that neither the diagram nor the theory says anything believable. The math given of the efficiency does not explain the efficiency defintion; the diagram makes no sense; and the heat exchange is nonsensical. You introduce the term "impeller blade" which is not marked on the diagram. Also is nonsensical the fact that the pressure drops quickly in each chamber. That's impossible too, according to the diagram. Because at 20 or 600 or 6000 revolutions per minute, the material that the engine is made of, does not have any chance to cool down. It loses the pressure after the exhaust happens, but from recent descriptions it seems that the loss of pressure happens before the exhaust process. I don't know if you are trying to start or perpetrate a hoax. Or if your source information is nonsensical. All I am saying is that with the facts and diagram given, as provided, nothing about this engine should work. It is not "my" opinion. It is the opinion of someone who understands physics--who happens to be me, but the main thing is that my understanding of physics is not linked to my ego. |

|

|

|

|

|

The diagram does not reflect any of what you said in the last few posts. I go by what I see. The photos, text, and diagram reflect exactly what I have described. And oddly, some of what you have described. The "cycle" diagram showed the difference in efficiency in theory (square area) vs real life engine with thermal losses and friction. I posted the diagram to show you why your 45% efficiency number was meaningless. Also, there is another iffy thing. You say the temperature will be much lower. How can that be? Burning gasoline burns at a certain temperature. It can't burn at a lower temperature. You missed the point completely. The efficiency of a thermal engine is based on the difference between the working temperature and the environment. Those mathematical laws (which are shown in the diagram) are mathematical facts that we can't change. Since the detonation cycle pressure wave imparts more energy into the impeller than a carnot, otto, or other piston engine imparts into the piston, the exhaust gas is cooler, i.e., lower temperature. This greater usage of the thermal energy of the fuel is what gives the new engine it's huge advantage in fuel efficiency. The ambient pressure affects the temperature, sure, but it does not affect the heat amount or temperature of what a certain carbohydrate molecule produces when it combines with oxygen. Your statement is false. Go back to school. The temperature of detonation of gas/air mixture will melt the pistons as any teenage hotrod fanatic knows. Almost anyone who drives a car knows "knock" is bad. The deeper we go into this, the more ill-described it sounds. The more you write about this subject, the less about the subject you understand. I don't doubt that the engine may be in the prototype stage. It would be easy to research that, and I don't do research. All I am saying is that neither the diagram nor the theory says anything believable. The math given of the efficiency does not explain the efficiency defintion; the diagram makes no sense; and the heat exchange is nonsensical. You have made it clear that you don't understand. That doesn't change the facts that what I posted and explained are real. And, unlike you, I research topics like this to make sure they are real because this type of engineering fascinates me. You introduce the term "impeller blade" which is not marked on the diagram. LOL Well, I guess that is true. It is the curved part that is moved by hot gas and goes round and round. Also is nonsensical the fact that the pressure drops quickly in each chamber. That's impossible too, according to the diagram. Because at 20 or 600 or 6000 revolutions per minute, the material that the engine is made of, does not have any chance to cool down. It loses the pressure after the exhaust happens, but from recent descriptions it seems that the loss of pressure happens before the exhaust process. Your post is nonsensical. The shock wave impacts the impellers and dissipates as the gas is allowed to escape where the temp drops quickly. This concept is clearly shown as a color change in the engine diagram. I don't know if you are trying to start or perpetrate a hoax. Or if your source information is nonsensical. All I am saying is that with the facts and diagram given, as provided, nothing about this engine should work. Massagetrade seems to "get" it. I "get" it. You just don't "get" it. It is not "my" opinion. It is the opinion of someone who understands physics--who happens to be me, but the main thing is that my understanding of physics is not linked to my ego. It would appear that your understanding of physics is not that great. It is really surprising that you don't know what an impeller looks like or how it works. You have made blatant errors in you statements in the thread (like your 45% efficiency gaff on the math)that would indicate that your physics education is lacking. I can assure you that mine is not. I would suggest that you do a little internet digging on this subject and stop acting the fool. One of the three test engines is being hooked up to a drive system sized for an electric vehicle. I would love to know the operational rpm, the step-down ratio for the generator, and other facts like that. Your baloney about the engine not being capable of working falls flat. I understand the operating principles of the engine. You do not. |

|

|

|

|

|

I looked for an update on the engine. There are four working prototypes now.

http://www.usnews.com/news/blogs/at-the-edge/2012/02/23/wave-disk-engine-could-be-new-hybrid-powerplant |

|

|

|

|

|

Bladon Jets also has a 40kg micro-turbine 50 kW powerplant already in the Pininfarina Cambiano concept car. Just shown at the Geneva show.

Here is the announcement and their website: Bladon Jets micro gas turbine generator is a key element of the Pininfarina Cambiano concept vehicle power train. Using its axial flow compressor technology this high performance range extender has the advantages of high power-small package density, multi fuel capability, good emissions characteristics and impressive NVH performance. The Cambiano drive system incorporates an APU (Auxiliary Power Unit) to charge the batteries and, when necessary, to supply energy directly to the motors: this is a 50 kW Bladon Jets micro turbine which normally runs on diesel but which can be calibrated to be compatible with various types of fuel. In addition to this advantage, the turbine is smaller than those of piston engines with a similar power delivery, it weighs just 40 kg, and generates low polluting emissions. http://www.bladonjets.com/applications/ |

|

|

|

|

|

Edited by

metalwing

on

Mon 05/21/12 06:56 PM

|

|

|

Bladon Jets also has a 40kg micro-turbine 50 kW powerplant already in the Pininfarina Cambiano concept car. Just shown at the Geneva show. Here is the announcement and their website: Bladon Jets micro gas turbine generator is a key element of the Pininfarina Cambiano concept vehicle power train. Using its axial flow compressor technology this high performance range extender has the advantages of high power-small package density, multi fuel capability, good emissions characteristics and impressive NVH performance. The Cambiano drive system incorporates an APU (Auxiliary Power Unit) to charge the batteries and, when necessary, to supply energy directly to the motors: this is a 50 kW Bladon Jets micro turbine which normally runs on diesel but which can be calibrated to be compatible with various types of fuel. In addition to this advantage, the turbine is smaller than those of piston engines with a similar power delivery, it weighs just 40 kg, and generates low polluting emissions. http://www.bladonjets.com/applications/ That looks like a good engine but the combustion cycle is completely different from a wave disc generator. Jets will usually accept a variety of fuels since it is a continuous burning open chamber blowtorch with compressor blades in the front and driven blades in the back. The fuel pumps and orifices have much to do with what kind of fuel it can burn. It just can't be too thick to pump. Since the wave disc generator relies on the shock wave of detonation, whatever fuel they find that works, like gasoline, must detonate within the rpm range and pressures of the engine. Turbine engines are extremely thirsty at low altitudes but make up for it at high altitudes where the cold dense air (it is dense because it is compressed) increases fuel efficiency. I'm a member of the EAA (Experimental Aircraft Association) and we all dream of the small homemade plane with the jet engine. Some have taken the small turbines used for APUs which the military sells as surplus, and have stuck them on small planes. A typical gasoline engine will burn six to nine gallons of fuel an hour and the small jet engine will burn thirty, if you're lucky. One of the small, homemade jet planes was used in a James Bond movie many years ago. It was the BD 5. It's twelve feet long. http://www.youtube.com/watch?v=2gPc2D9FMOo |

|

|

|

|

|

I was wondering where the concept of running the engine at only 1 rpm came from till I saw what I had written.  I thought you meant to use a different unit - like 'rotating at 1 khz' or something. Also is nonsensical the fact that the pressure drops quickly in each chamber. That's impossible too, according to the diagram. Because at 20 or 600 or 6000 revolutions per minute, the material that the engine is made of, does not have any chance to cool down. It loses the pressure after the exhaust happens, but from recent descriptions it seems that the loss of pressure happens before the exhaust process.

I think you are right about the temperature of the material - I can accept that the material itself doesn't have time to cool down. As I understand it (?), it doesn't need to. Only the gas needs to cool down, and I believe it will as it exhausts. I don't know if this helps, but it looks to me like the engine as a whole is continuously, smoothing exhausting. Massagetrade seems to "get" it.

Thought I've been commenting on it, I still haven't take the time to read about it or really think about it, and I don't feel that I do 'get it' yet. |

|

|

|

|

|

I was wondering where the concept of running the engine at only 1 rpm came from till I saw what I had written.  I thought you meant to use a different unit - like 'rotating at 1 khz' or something. Also is nonsensical the fact that the pressure drops quickly in each chamber. That's impossible too, according to the diagram. Because at 20 or 600 or 6000 revolutions per minute, the material that the engine is made of, does not have any chance to cool down. It loses the pressure after the exhaust happens, but from recent descriptions it seems that the loss of pressure happens before the exhaust process.

I think you are right about the temperature of the material - I can accept that the material itself doesn't have time to cool down. As I understand it (?), it doesn't need to. Only the gas needs to cool down, and I believe it will as it exhausts. I don't know if this helps, but it looks to me like the engine as a whole is continuously, smoothing exhausting. Massagetrade seems to "get" it.

Thought I've been commenting on it, I still haven't take the time to read about it or really think about it, and I don't feel that I do 'get it' yet. If you sent shock waves of exploding air into your roof exhaust vent, it would spin like crazy. If you blocked off the sides so that the air was forced through half the vanes, rotor, impellers ... as the case may be, it would still spin like crazy. The big "new idea" here that seems to trip people up is the fact that the new engine does not work on the old common heat engine/ expanding gas scenario that pretty much all the rest work on. It is the power of the shock wave that was made from the fuel that powers the engine, not the smooth burning of gas. Less energy is wasted so more energy gets used. |

|

|

|

|

|

The big "new idea" here that seems to trip people up is the fact that the new engine does not work on the old common heat engine/ expanding gas scenario that pretty much all the rest work on. It is the power of the shock wave that was made from the fuel that powers the engine, not the smooth burning of gas. Less energy is wasted so more energy gets used. Yes, and its not obvious at first which of the 'standard heat engine' principles still apply, and which need to be set aside. |

|

|

|

|

|

The big "new idea" here that seems to trip people up is the fact that the new engine does not work on the old common heat engine/ expanding gas scenario that pretty much all the rest work on. It is the power of the shock wave that was made from the fuel that powers the engine, not the smooth burning of gas. Less energy is wasted so more energy gets used. Yes, and its not obvious at first which of the 'standard heat engine' principles still apply, and which need to be set aside. In the other cycles it is 100% increase in pressure due to increase in temperature. The new engine has some large amount of kinetic energy to slam into the curved blades in rapid pulses. It reminds me of the WWII German V1 pulse jet rocket (which had no detonation cycle). The V1 had so many pulses of power, it seems continuous. The rotation of the impellers on the rotor are continuous. They are kept turning by the waves of pressure shock waves pushing rotation. Piston engines too run at continuous speed with pushes of power at intervals. Same thing. Only the gas turbine and rocket are truly continuous. |

|

|

|

|

|

Bladon Jets also has a 40kg micro-turbine 50 kW powerplant already in the Pininfarina Cambiano concept car. Just shown at the Geneva show. Here is the announcement and their website: Bladon Jets micro gas turbine generator is a key element of the Pininfarina Cambiano concept vehicle power train. Using its axial flow compressor technology this high performance range extender has the advantages of high power-small package density, multi fuel capability, good emissions characteristics and impressive NVH performance. The Cambiano drive system incorporates an APU (Auxiliary Power Unit) to charge the batteries and, when necessary, to supply energy directly to the motors: this is a 50 kW Bladon Jets micro turbine which normally runs on diesel but which can be calibrated to be compatible with various types of fuel. In addition to this advantage, the turbine is smaller than those of piston engines with a similar power delivery, it weighs just 40 kg, and generates low polluting emissions. http://www.bladonjets.com/applications/ That looks like a good engine but the combustion cycle is completely different from a wave disc generator. Jets will usually accept a variety of fuels since it is a continuous burning open chamber blowtorch with compressor blades in the front and driven blades in the back. The fuel pumps and orifices have much to do with what kind of fuel it can burn. It just can't be too thick to pump. Since the wave disc generator relies on the shock wave of detonation, whatever fuel they find that works, like gasoline, must detonate within the rpm range and pressures of the engine. Turbine engines are extremely thirsty at low altitudes but make up for it at high altitudes where the cold dense air (it is dense because it is compressed) increases fuel efficiency. I'm a member of the EAA (Experimental Aircraft Association) and we all dream of the small homemade plane with the jet engine. Some have taken the small turbines used for APUs which the military sells as surplus, and have stuck them on small planes. A typical gasoline engine will burn six to nine gallons of fuel an hour and the small jet engine will burn thirty, if you're lucky. One of the small, homemade jet planes was used in a James Bond movie many years ago. It was the BD 5. It's twelve feet long. http://www.youtube.com/watch?v=2gPc2D9FMOo

Bob and Corkey

|

|

|

|

|